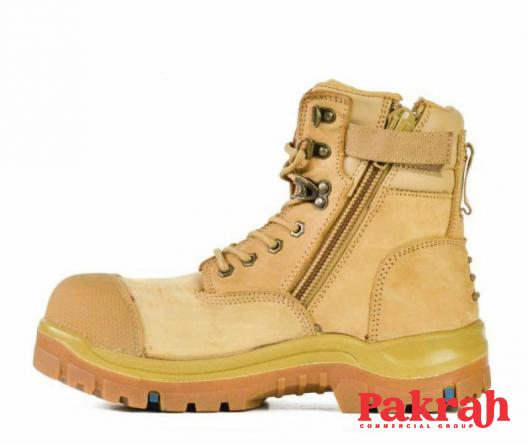

No Lace Safety Boots are a type of shoe or boot that is designed for work, industrial and factory environments and minimize damage to the foot. No Lace Boots Materials are usually produced in the form of steel toe or composite toe, which greatly reduces the amount of damage when heavy objects fall.

Industrial shoes prevent slipping, slipping and slipping of the foot in oily and greasy contaminated environments. There is a wide range of work shoes, the type of shoes should be chosen correctly according to the activity and the nature of the danger that may threaten the person.

Materials Used in the Manufacture of No Lace Safety Boots

PU outsole

PU outsole

This type of material is the most common in the production of work shoes and has a high resistance to wear, corrosion and slip. The melting point of this material is 80 degrees Celsius and it is possible to use this shoe in hot environments with a temperature of fewer than 80 degrees.

Rubber plastic outsole

This type of outsole is used for shoes that are to be used in environments with electrical hazards. It insulates electricity and has lighter weight.

TPU outsole

Another type of material in the production of shoes can be used in acidic environments and high temperatures. This outsole has more weight than other models but instead, its resistance and efficiency are much higher.

In some cases, the sole of the shoe is produced in two layers of PU-PU material or two layers of PU-TPU layer which leads to increased strength, longevity and efficiency. Temperature tolerance of this type can reach up to 170 degrees.

in What Cases Do No-Lace Safety Boots Protect the Foot?

No Lace Boots Protection should be used in all industries where there is a possibility of a foot injury. For working indoors or in open spaces such as construction project sites and mines, it is better to use shoes with S3 standard and if there is a possibility of flooding, S5 type. For work in the food industry and its processing, which is usually done indoors and in dry environments, shoes with S1 or S1P standards are suitable and depending on the type of workplace flooring, it may be non-slip or heat and cold insulation to be used.

No Lace Boots Protection should be used in all industries where there is a possibility of a foot injury. For working indoors or in open spaces such as construction project sites and mines, it is better to use shoes with S3 standard and if there is a possibility of flooding, S5 type. For work in the food industry and its processing, which is usually done indoors and in dry environments, shoes with S1 or S1P standards are suitable and depending on the type of workplace flooring, it may be non-slip or heat and cold insulation to be used.

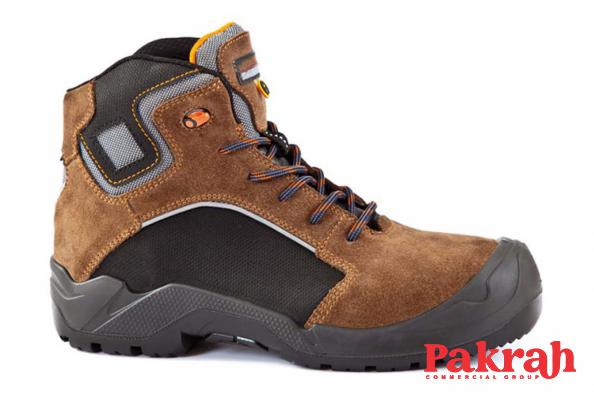

Anti-chemicals should be used in laboratory environments and chemical industries where there is a risk of spraying or accidental contact with chemicals. Can be selected from standard S1 and S2 with spray resistance. In the automotive industry, shoes must have certain characteristics depending on the type of hazard. Required during activities such as welding shoes with standard S1 with Hero feature.

Types of safety shoes are: Rubber shoes, boots or boots Shoes with shock-resistant steel or composite toe Shoes with metal soles Electrical insulation shoes Refractory shoes Put a shoe for use on ordinary shoes Fire shoes to fight and participate in various firefighting operations Corrosion-resistant butyl shoes

The most important benefits are: Protect your feet from all kinds of injuries and threats to the work environment Avoid frustration and slipping Protection against contact with electric current and electric shock Protection against high heat Protect your feet from various weather conditions, especially in open environments such as cold and rain Prevent the penetration of moisture and create unfavorable conditions inside the shoes

Manufacturers of No Lace Safety Boots

The manufacturer of No Lace Boots Manufacturers is a production group that produces all kinds of work shoes by using machines and equipment as well as raw materials.

The manufacturer of No Lace Boots Manufacturers is a production group that produces all kinds of work shoes by using machines and equipment as well as raw materials.

The manufacturer of safety shoes must pay enough attention to the quality, durability, reasonable price and customer needs in producing their products. Always try to use the latest technology and standards in the production of its products.

In the production and manufacturing stage of the mold, always ensure the correct operation and use of quality materials. The quality of raw materials and injectables used and the use of the right combination leads to the production of a quality product. Failure to comply with any of these can lead to the production of shoes that do not have the necessary quality, quality and standards.

Your comment submitted.